Moulded System

At Zeonics Systech we have several Vacuum Vessels and specialised degassing systems where we manufacture Large moulded structures . The materials which we can mould are all electrical grade and can withstand high voltage stresses. Several materials are used for moulding like Epoxy filled and unfilled, Polyurethane, Castor Sauce, Mineral Oil Impregnation and Epoxy moulded on top, Gas filled and moulded on top. We specialise in sub contrary Vacuum moulding as a standard part of our Business and we have dedicated containers for moulding all these materials under specific conditions. Several inert atmospheres like Nitrogen, Argon are available during moulding of critical components. We degass all the components as well as containers before moulding. Standard conditioning technique is applied to moulds before conditioning them for moulding and once moulded they are continously monitored in our chambers for deformity if any. Several aerospace components used for critical applications are moulded at our end with utmost precision. We have moulded components which have withstood the following severities.

- Max. Temperature : 1250C

- Vibration: 1 hour in each orientation 0.02g2/Hz from 5 to 60Hz 0.05g2/Hz from 60 to 1000Hz

- Shock: Severity 40g for 6ms 3shocks in each direction.

- R.H @ 500C - 95%

- Acceleration : Constant acceleration-50g in all axis 10min. each.

- Altitude : 50Km

- Min.Temperature : -600C

- Bump test 4000+/- 10Bump at a peak acceleration of 400+/-40m/sec.

Our Capacity for moulding assemblies are as follows:

Maximum Diameter of Assembly : 750mm

Maximum Height of Assembly : 1000mm

Maximum Voltage Withstanding Capacity : 400KVDC.

Weight / Job : 105Kgs

Most of our castings are compensated for Temperature fluctuation and the electrical connection are given as flying wires for suitable connections.

|

|

Kindly contact us for specific requirement

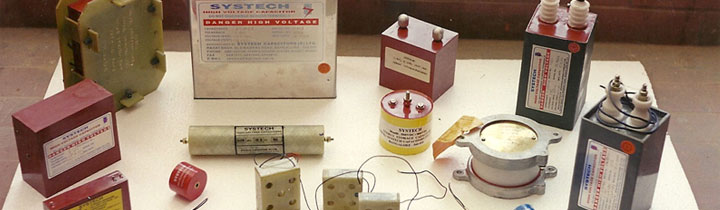

High Voltage Multiplier Assemblies

At Zeonics Systech we have been manufacturing high voltage assemblies up to 1Million Volts. These assemblies can generate voltages in the order of 1 Million Volts. Standard System are available with different outputs to suit Customer Requirements.

| Type of Frequency | Output Voltage No Load | Output Voltage Full Load | Full Load Current | Inverter Input (KVAC) | Input frequency |

| ZE/HVA/5/25 | 40KVDC | 25 | 5 mA | 5 | 20kHz,+/- 5KHz |

| ZE/HVA/5/30 | 45KVDC | 30 | 5 mA | 5 | 20kHz,+/- 5KHz |

| ZE/HVA/5/40 | 70KVDC | 40 | 5 mA | 5 | 20kHz,+/- 5KHz |

| ZE/HVA/10/50 | 100KVDC | 50 | 5 mA | 10 | 20kHz,+/- 5KHz |

| ZE/HVA/10/80 | 140KVDC | 80 | 3 mA | 10 | 20kHz,+/- 5KHz |

| ZE/HVA/10/100 | 220KVDC | 100 | 3 mA | 10 | 20kHz,+/- 5KHz |

| ZE/HVA/20/200 | 350KVDC | 200 | 3 mA | 20 | 20kHz,+/- 5KHz |

| ZE/HVA/25/500 | 700KVDC | 500 | 1 mA | 25 | 20kHz,+/- 5KHz |

| ZE/HVA/40/1000 | 1400KVDC | 1000 | 500microA | 40 | 20kHz,+/- 5KHz |

The Input has to be given through a high frequency Inverter with a suitable AC output of 5KV to 40KVAC at 20 to 25kHz If the Inverter has only a low voltage output then we can supply to you a suitable Transformer for this application. Kindly contact us with your requirements. All the H.V. Multipliers are fixed and installed on a parallely mounted and moulded system .The complete Assembly is filled with Gas in a sealed Fibre Glass Enclosure with a suitable Gas filling arrangement. The Input terminals are normally marked as X and Y for connecting a required H.V. H.F. transformer connections with each assembly. The required frequency and High Voltage capability of the Transformer is also mentioned.

Kindly contact us for specific requirement